Pre-pinched Port

Mechanically Pinched

Single Pinch Mechanism

Simple Economical Design

- Low pressure drop

- No packing

- Drop tight closure

- On/Off or throttling service

- Linear throttling characteristic

- Fail Open or Fail Closed pneumatic actuators

- Long lasting compression molded sleeve

Applications: Ideal for automatic control of abrasive, viscous, and corrosive fluids including wastewater, mine slurry, chemicals, cement, pulp , powder and pellets.

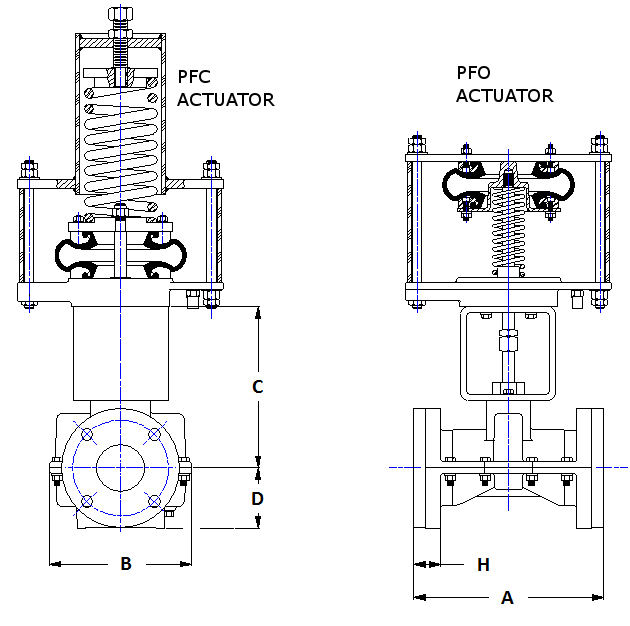

Operation: A pre-pinched pneumatically operated valve with the maintenance free Onyx Actuator. The actuator uses a spring for reliable fail-open (PFO) or fail-closed (PFC) operation in a range of sizes. It does not require lubricated air.

Specifications:

- Flanges: ANSI STD. 125/150 lbs

- Housing: Cast iron, ASTM A48, Class 35

- Stem: 303 stainless steel

- Yoke: Carbon steel

- Actuator: Cast iron/PVC

Options:

- Epoxy paint

- Sleeve elastomer

- 316 stainless steel stem

- ANSI STD 300 lbs. Flange

- Secondary containment package

- Auxiliary hand wheel

- Positioners

- Solenoid valves

- Limit switches

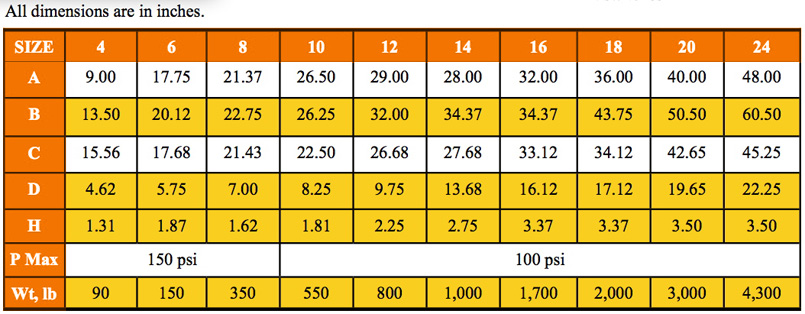

Valve Sizes:

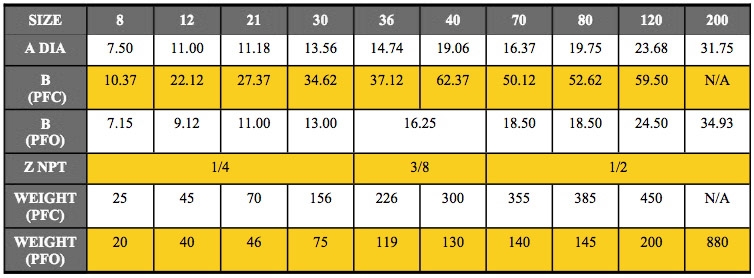

Actuator Sizes:

Actuator Selection Information

Click to review options

Double Acting Cylinder

PFO - Pneumatic Fall Open

PFO - Pneumatic Fall Open

PFC - Pneumatic Fall Closed

PFC - Pneumatic Fall Closed

PFO - Pneumatic Fall Open

PFO - Pneumatic Fall Open

PFC - Pneumatic Fall Closed

PFC - Pneumatic Fall Closed

All mechanically pinched pneumatic valves are available with 2 families of pneumatic actuator:

- A conventional air double acting cylinder. Air is applied alternating to the cylinder head and cylinder bottom to open and close the valve. This is inherently a Fail-in-last-position actuator.

- Onyx "Bomb Proof" zero maintenance actuator. This actuator is designed around a firestone airbag for the most robust construction and zero maintenance. It is available in two configurations:

- Valve Size

- Fail Mode

- Process Pressure