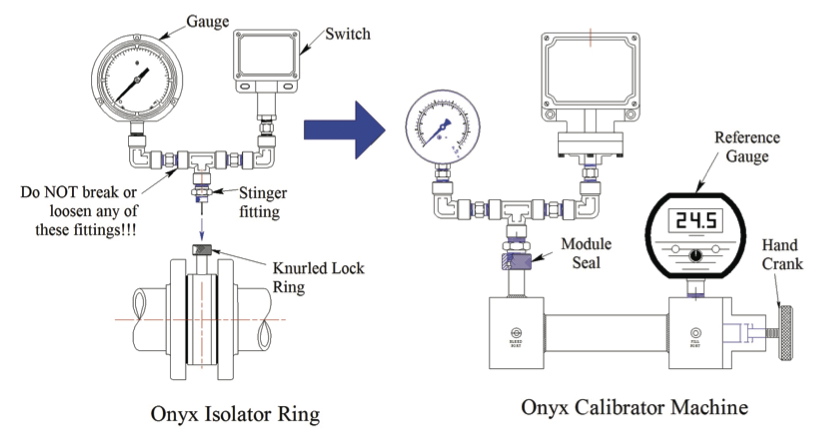

Onyx Valve Calibrating Machine

Onyx Valve Calibrating Machine provides a reliable method to calibrate gauges, switches, or transmitters originally supplied as integral components on Onyx Isolator Rings.

This rugged machine is light weight, completly portable, and requires no external power, making it the ideal companion for field service. It can generate any pressure from near full vacuum to +400 psi. Calibrating instruments on a conventional isolator ring is virtually impossible: As soon as you break the fitting connections, you risk loosing fill fluid or getting air bubbles into the instrument. Air must be excluded because it will compress to a smaller volume under pressure. This forces the rubber sleeve to stretch, increasing the error in the gauge reading. Beyond a certain point the rubber reaches its limit and pressure indication ceases. Even a miniscule air bubble can adversely affect performance, leaving the pressure instrument worse off than before you attempted to calibrate it.

The Onyx Calibrating Machine provides a simple means to circumvent this problem. The Onyx Calibrating Machine includes the patented Onyx Module Seal as the conection point for the instrument to be calibrated.

Gauges, pressure switches, transmitters, or any combination of these instruments can easily be temporarily removed from the Onyx Isolator Ring, attached to the calibration machine for verification, then put back on the isolator ring. To calibrate the instrument, simply turn the crank to build up the required pressure and compare the reading on the process instrument to the reference gauge.

The Calibrating Machine is available with a variety of reference gauges, either mechanical and electronic (battery powered), with analogue or digital readout, with accuracy equal to or better than ANSI class-3A, and tracability to NIST certificates are available.